On January 5th, reports indicate that TSMC's 2nm (N2) advanced process is set for an initial production capacity of 35,000 wafers per month, with plans to surge to 140,000 wafers per month by the end of 2026. This target significantly exceeds previous market estimates of 100,000 wafers, showcasing TSMC's aggressive expansion in leading-edge semiconductor manufacturing.

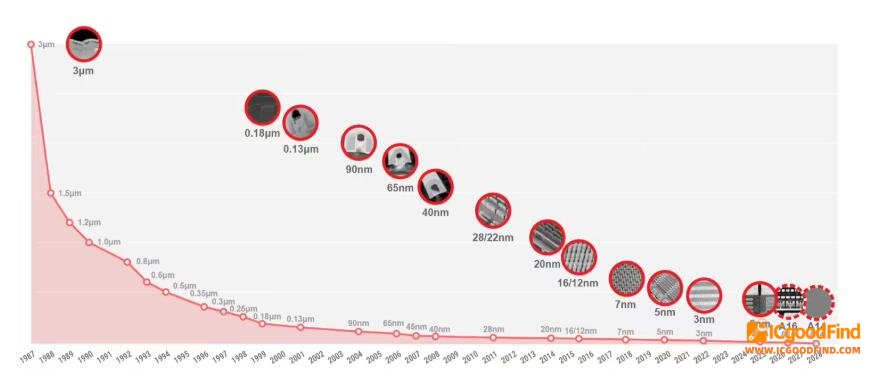

The primary 2nm capacity will be supported by two super fabs: Phase 1 of Fab 20 in Hsinchu and Phase 1 of Fab 22 in Kaohsiung. The second phase (Phase 2) of both facilities is scheduled to begin production within 2026, entirely dedicated to the 2nm process, enabling this major capacity leap. As the key node transitioning fully to the GAA architecture, TSMC's 2nm offers significant breakthroughs in performance and power efficiency. Since its launch, it has attracted intense demand from global chip leaders, with 2026 capacity fully booked in advance. Major clients including Apple, Qualcomm, MediaTek, and AMD are securing their allocations.

Industry analysts are optimistic about the 2nm node's market performance, expecting it to contribute substantially to TSMC's revenue starting in the second half of 2026. Driven by strong demand for AI chips and high-end smartphone processors, combined with the premium pricing of the 2nm process, this generation is poised to potentially outperform the previous 5nm and 3nm nodes, becoming TSMC's "most successful node generation". This would further solidify its dominant position in global advanced foundry services. While competition from Samsung and Intel in the 2nm race is intensifying, TSMC currently holds an edge in ramp-up speed and its established customer ecosystem.

ICgoodFind Perspective: TSMC's aggressive 2nm expansion will reshape the high-end chip supply chain. We will continue tracking these developments to help the industry leverage new opportunities in advanced nodes.